How much do you know about CMOS barcode scanner?

Before barcode scanners, the only way to track products and inventory was by manually counting every item on a store's shelves and in the warehouse.

Most inventories were done infrequently, while ordering decisions were based on crude estimates and arbitrary feelings. Counting, tracking, and managing inventory was time-consuming and expensive.

Today, thanks to barcode scanning technology, inventory tracking and management happens digitally, in a matter of seconds. But just how does a barcode scanner work?

Ahead, learn more about CMOS barcode scanner.

What is CMOS barcode scanner?

CMOS barcode scanner, also known as 2D area imager, uses a CMOS camera similar to the cameras that are common in modern smartphones. They consist of a CMOS sensor, which together with a small lens form the actual camera, plus a high-speed processor with a big memory that processes the images delivered by the camera. Other than decoding alphanumeric information, these scanners also interpret codes that contain binary data, including images, voice, loyalty programs, and URLs.

Here's a breakdown of the barcode scanning process:

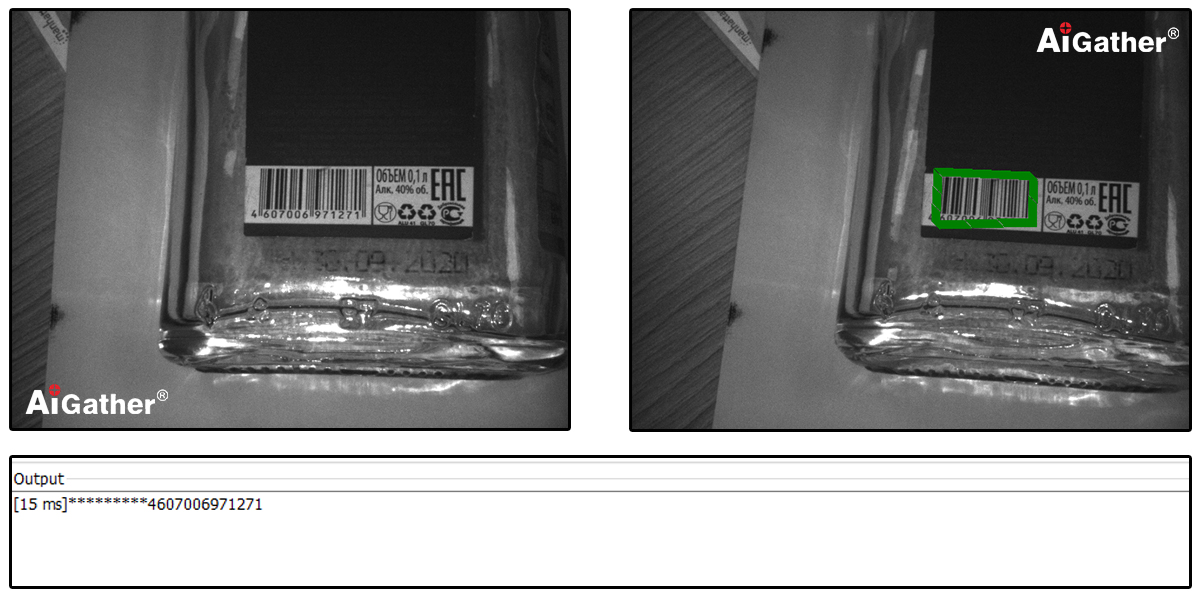

The barcode scanner shines a light source onto the barcode, capture an image field and then decode the barcode with an algorithm software and relays the information back to a computer or other electronic device. Due to 2D imagers having a wider scope or area than other barcode scanners, a 2D imager can read virtually any barcode including 1D, 2D, QR code, Data Matrix, and PDF417 in a paper or screen.

With two-dimensional reading capabilities, a 2D scanner captures a more detailed and intelligent image than a 1D scanner, whether you're scanning outdoors or scanning dirty or damaged barcodes. This makes a 2D scanner an intelligent choice for long-term scanning.

As the popularity of barcode readers grows, so do the options available to retailers to capture information. Let's take a look at four types of CMOS barcode scanners.

Desktop scanners

Desktop scanners are used by being mounted on the desktop. This model is mostly used at the cashier side of the markets or in places selling retail products.

Since the desktop barcode reader is mounted on the desktop, the label or barcode to be read is read by passing it next to or under the device. Thanks to their wide scanning area, desktop scanners offer fast, accurate barcode scanning on items that pass over them, without needing to point the scanner or trigger the device.

Handheld scanners

Handheld barcode scanners are user-friendly devices, it uses a point-and-scan functionality and trigger-like mechanism to activate the scanning operation and accurately capture various barcode symbologies, including 1D, 2D, postal barcodes.

The scanners also can use radio frequency or Bluetooth technology to integrate with devices like smartphones, tablets, laptops, or retail point-of-sale (POS) applications, and then transmit data, such as inventory updates, in real time.

Embedded scanners

Embedded scanners usually have a small body, can be embedded in any device for scanning code to identify other items, by using the intelligent image recognition algorithm. Common examples include retail POS systems, checkout counters, kiosk or vending machines.

Fixed mount scanners

A fixed mount barcode scanner is mounted in a stationary position or fixed location at a specific angle and distance. Common examples include retail POS systems, checkout counters, or vending machines.

You can easily integrate a fixed mount scanner with existing systems for efficient and accurate barcode scanning in high-speed environments, like retail stores, warehouses, assembly lines, and distribution centers.

Upgrade your business with a barcode scanner

The right barcode scanner for your business improves productivity and efficiency by making it faster to catalog, track, and manage your inventory across locations. Plus, it reduces human error and accurately improves transactions for your customers.

When choosing a barcode scanner, think about features, your budget, and your business goals and needs—to find the most suitable one than the best one.